The ironing belt is one of the indispensable equipment in the laundry industry.

It uses high temperature and pressure to iron clothes and restore their original smoothness and beauty.

In commercial laundry services, the use of ironing belts can significantly improve work efficiency and reduce manual ironing time and labor costs.

In addition, high-quality ironing results can enhance the customer’s overall impression of the laundry service.

Although ironing belts play an important role in the washing process, many users find that their lifespan is much shorter than expected.

Quickly worn flatwork ironer belts necessitate frequent replacements, escalating costs, and potentially harming ironing quality and customer satisfaction.

In the following sections, we will delve into the reasons why flat press belts wear quickly.

These include material quality, frequency of use, improper operation, and environmental factors.

At the same time, we will also provide some practical maintenance and care suggestions to help extend the service life of the ironing belt.

Effects of Low-Quality Materials: The material quality of an ironing belt directly affects its durability.

Lower-quality materials may not have sufficient heat and abrasion resistance, making them more susceptible to wear and damage during use.

Effects of frequent use: The service life of an ironing belt is closely related to its frequency of use.

Frequent use will increase the mechanical stress on the flatwork machine belt and accelerate material fatigue and wear.

Improper operation: The skill and experience of the operator have a significant impact on the wear and tear of the ironing belt.

Improper operation, such as too high a temperature setting, uneven pressure distribution, or wrong ironing technique, can cause rapid wear of the Flatwork ironer Feeder Belt.

Environmental factors: The operating environment of the flatwork machine belt, such as humidity, temperature, and dust levels, can affect its performance and lifespan.

High temperature and high humidity environments may accelerate the aging and degradation of materials.

Other reasons: There is a lot of dirt on the groove surface of the industrial ironing machine and the friction increases.

Correct ironing skills: Understand the ironing requirements of clothes of different materials and adopt appropriate ironing methods.

For example, for light and thin fabrics, lower pressure and temperature should be used, while for thicker fabrics, higher pressure and temperature may be required.

Pressure control: Applying pressure evenly is the key to achieving good ironing results.

Uneven pressure may cause damage to the fabric or wear of the ironer Belts.

Appropriate temperature: Setting the correct temperature is crucial to protecting both the ironing belt and the clothes.

Too high a temperature will not only damage the clothes but may also accelerate the aging and wear of the flatwork machine belt material.

Temperature regulation: Adjust the temperature of the ironer Belts according to the material of the clothes.

For example, synthetic fibers may require lower temperatures, while cotton or linen may require higher temperatures.

Avoid overloading: Do not exceed the maximum load capacity of the ironing belt.

Overloading will not only damage the Flatwork ironer belt but may also cause safety accidents.

Load management: Arrange ironing tasks to prevent long-term use and allow the ironing belt to rest periodically to reduce wear from overheating or overuse.

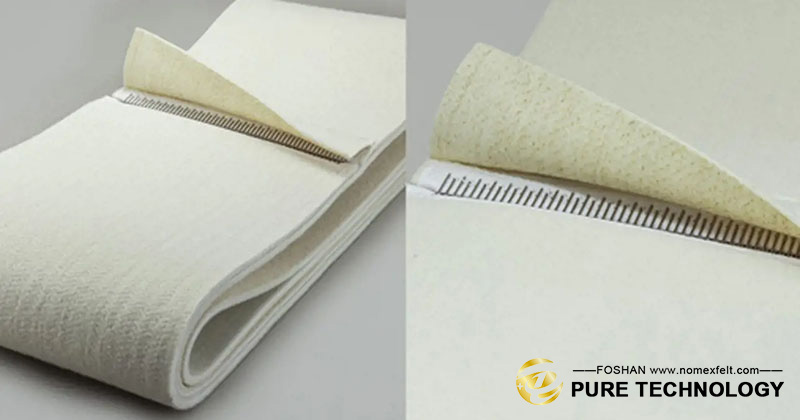

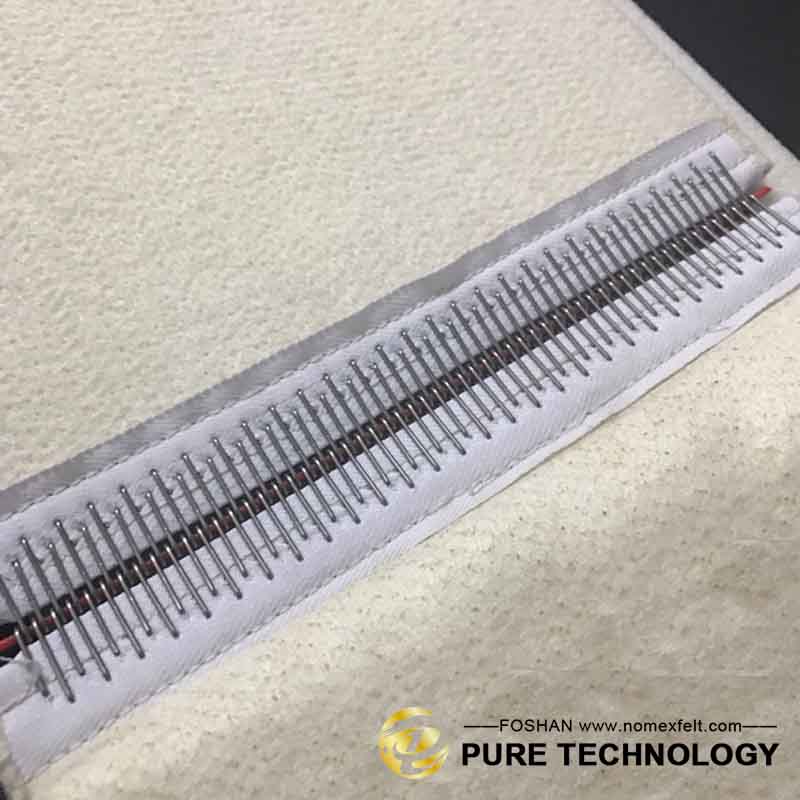

Selecting a top-notch ironing belt is key for ironing outcomes, equipment longevity, and sustained operational costs.

Durability: High-quality flatwork machine belts are made with more durable materials that can withstand prolonged heat and pressure, resulting in a longer lifespan.

Consistent ironing results: Quality ironer belts evenly distribute heat and pressure for consistent, flat ironing, preventing local overheating and unevenness.

Reduced Maintenance: Increased durability means less frequent replacements, which reduces downtime and maintenance and increases overall efficiency.

Energy Saving: A high-quality ironer Belt may have better insulation properties, reduce heat loss, and improve energy efficiency.

Adaptable: High-quality Flatwork ironer belts are designed to adapt to a variety of ironing conditions and the ironing needs of different types of clothing.

Reduced long-term costs: While the initial investment may be higher, reduced replacement and maintenance can significantly reduce costs in the long term.

Safety performance: High-quality ironing belts take safety factors into consideration during the design and manufacturing process to reduce operational risks.

We must realize that the maintenance and care of ironing belts is an integral part of daily operations.

Regular checks, timely replacements, and proper storage can reduce wear and enhance equipment reliability.

I hope they will be helpful to you. If you have any other questions, please feel free to communicate with me at any time.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...