In the aluminum extrusion process, the extrusion process is performed immediately after the aluminum rod is heated.

In this process, defects (such as bending, deformation, short stripes, and scribes) and invisible defects (such as adsorption particles) are easy to appear.

During the production process, problems should be solved in time. Summarize the cause of the defect. The aluminum profile products produced are not good in appearance, It is not easy to say that if you are not careful,

It is not easy to say that if you are not careful, it will easily cause scrap and bring unnecessary losses to the enterprise.

Let’s first take a look at the defects such as short strips, bending, and scribing during the extrusion of aluminum profiles. These are the most prone to problems, such as the following reasons:

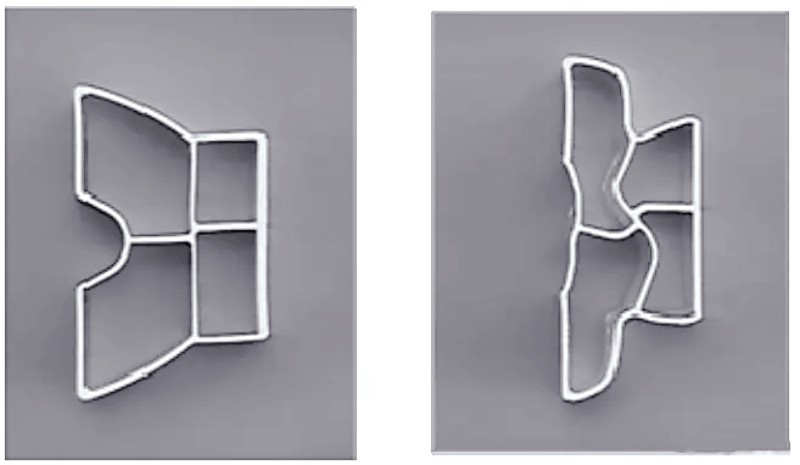

First: The size between the aluminum extrusion cylinder and the aluminum extrusion pad is not matched, and the poor die hole causes the aluminum metal particles to be pressed into short strips. Therefore, when choosing a die, you must choose the appropriate size of the die pad and support pad. If the size is not suitable, it can be installed appropriately.

Second: the aluminum extrusion die is not replaced in time, the use time is too long, the hardness is not enough, and the extrusion profile is elastic and easy to bend.

Third: Affected by the extrusion speed and extrusion temperature, if the extrusion speed is too fast and the extrusion temperature is too high, the flow speed of the profile will also increase,

the degree of deformation of the die will increase, the metal flow speed will increase, and the deformation resistance will decrease. Relatively weakened,

it is easy to cause sticking to aluminum, increase the surface roughness of the tool and mold, and form a line on the surface of the profile, affecting the appearance.

These defects have some common characteristics: the surface of the aluminum profile is white,

longitudinally distributed and has a certain concentration, intermittent or dotted, more tails than the front,

and the most important thing is that the color is gray-black after oxidation, which seriously affects the appearance and quality.

How to solve the defects that affect the quality of aluminum profiles?

The selection of aluminum extrusion dies is very important in the production process of aluminum profiles. It must be strictly stipulated that the size error of the extrusion cylinder and the extrusion pad should not exceed 0.1mm;

The error of the extruded barrel and the working part and the non-working part, that is, the chamfer of the inlet of the extrusion barrel, does not exceed 1mm;

To ensure the hardness of the aluminum extrusion die and the smoothness of the toothless working belt, to ensure the quality of the aluminum rod is qualified.

Only by adopting the correct aluminum extrusion process can the produced aluminum profile products be beautiful and of good quality.

There is also the use of high-quality endless belts. Click the link to get the ring belt price.

Hope the information shared above is helpful to you. Follow us for other aluminum industry information.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...