The extrusion machine is the leading equipment for the production of aluminum profiles. The quality of the extrusion machine affects the shape, size, and appearance quality of the aluminum profiles. When purchasing an extrusion press machine, many companies must first understand the model, extrusion capacity, and grade of the press, because there are many types of extruders.

How to determine the tonnage of the aluminum profile extrusion machine? This is an aspect that aluminum profile manufacturers must consider when purchasing extrusion machines.

Now explain how to choose the tonnage of the extruder.

The tonnage of the extrusion machine is calculated according to the size of the extrusion force, and the cargo represents the extrusion force.

Common tonnages are 500t, 630t, 800t, 1000t, 1200t, 1800t, 2500t, etc.

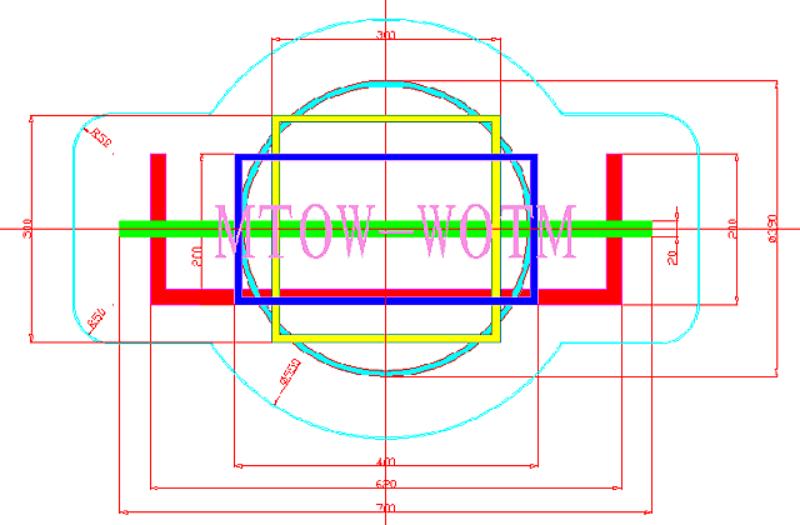

The tonnage is proportional to the diagonal of the aluminum profile. As shown in the figure: the size of the discharge port of the large extruder and the diagonal requirements of the extruded profile.

The aluminum extrusion machine model and the specifications of the aluminum profile should complement each other.

A suitable extruder can extrude a reasonable range of alu profiles. Generally, the extrusion ratio is determined according to the profile diagram of the aluminum profile, and then the size of the extruder to be used is determined.

The determination of the extrusion machine is mostly calculated according to the extrusion ratio, which has something to do with the requirements of the aluminum factory.

For example, an aluminum extrusion ratio is only 5-15,

In this case, the aluminum profile factory should replace the extruder machine with a larger tonnage for production.

However, the aluminum material factory chooses a simpler way for aluminum profiles, which is to require the aluminum die factory to design the alu mold without changing the press.

At this time, the mold factory will still complete the design.

So now die designers often design and produce molds according to the information specified by factories.

| Felt Conveyor Belt, PBO Roller, and Spacer Bar Cover for Cooling table. Contact us for a price. [email protected] |

Let’s preliminarily select the type of extruder. The first thing to consider is the tonnage of the extruder.

When selecting the tonnage of the extruder, it is generally necessary to calculate the extrusion ratio of the extruder first.

The extrusion ratio, also known as the extrusion coefficient, refers to the ratio of the extrusion cylinder’s cross-sectional area to the aluminum profile’s total cross-sectional area.

It is the main parameter used to measure the deformation of aluminum alloy in the production of aluminum profiles, expressed by the following formula:

Among them, Ft represents the cross-sectional area of the aluminum ingot filled in the extrusion cylinder, expressed in mm²;

ΣF1 represents the total cross-sectional area of the extruded profile, expressed in mm²;

During the extrusion of aluminum profiles, the amount of deformation of the aluminum alloy can also be expressed by the degree of deformation: ε=λ-1

If the extrusion processing method is used, the extrusion ratio is limited. The extrusion ratio λ of the primary extrusion aluminum profile and the aluminum rod is greater than 8-12 during extrusion, and the extrusion ratio of the blank for secondary extrusion There is no limit to the pressure ratio.

The summary is to use the cross-sectional area of the extruded ingot ÷ the cross-sectional area of the extruded profile,

It can also be calculated in other ways,

The length of the extruded profile ÷ the length of the ingot used for extrusion.

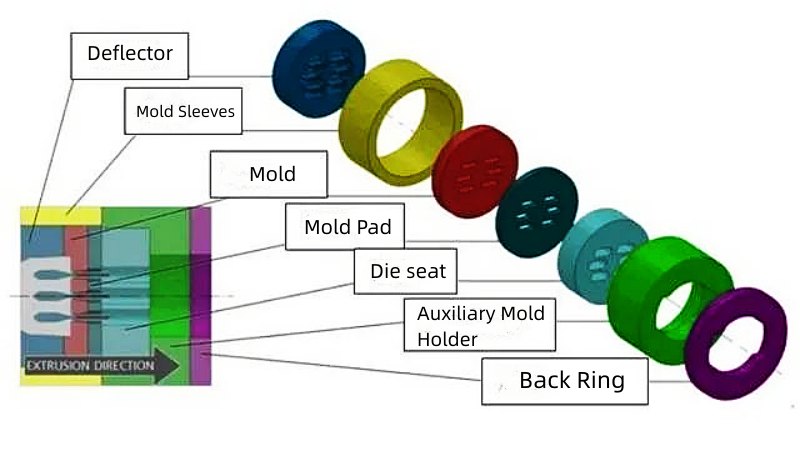

Before determining the tonnage of the extruder, it is necessary to know the cross-sectional shape of the profile, choose the size of the die, the structural form of the mold,

In this way, it can be determined whether the extrusion is a hollow profile or a solid profile. The tonnage of the extrusion machine required for these two different structural profiles is different.

There are many classifications of extrusion machines. According to the extrusion capacity, they can be divided into small, medium, large, and heavy extruders.

The extrusion capacity of each type of extrusion machine is limited,

Extrusion capacity is usually expressed in MN, that is, tonnage,

The tonnage of the 6063 aluminum profile extrusion press machine used in industrial production has the following standards:

| 500 | 600 | 800 | 1000 | 1200 | 1350 | 1600 | 1800 | 2000 | 2400 |

| 2800 | 3000 | 3500 | 4000 | 6000 | 10000 | 12500 | 15000 | 20000 |

Extrusion machines of the above tonnage can be used to extrude aluminum profiles of 6063 profiles.

Aluminum profile manufacturers should consider the extrusion coefficient of the extrusion machine, the cross-sectional shape of the profile,

and the size of the mold when selecting the tonnage of the aluminum profile extrusion machine, as well as their production conditions and product requirements.

Determining the proper extruder tonnage requires calculating the deformation of the metal,

In this way, qualified aluminum profile products can be extruded without causing unnecessary economic waste to the enterprise.

Before investing in an aluminum profile factory to purchase an extrusion machine, we always consider the daily output, annual output value, and production efficiency of the extrusion machine. How is the yield calculated?

01

There are many kinds of extrusion machines, such as aluminum profile extrusion machines, copper extrusion machines, plastic extrusion machines, metal extrusion machines, food extrusion machines,

Among them, the aluminum extrusion machine we want to introduce is mainly suitable for the extrusion processing of aluminum alloy profiles and bars and adopts a prestressed composite frame structure.

Front feeding forward extrusion mode, oil pump direct drive, equipped with advanced electromechanical hydraulic control system and components, and a complete set of mechanized auxiliary equipment,

Use safe high-performance PLC and industrial control computers for control and data analysis.

02

Most of the extrusion machines with large production capacities are calculated according to the extrusion ratio.

This is also related to the requirements of the aluminum profile factory.

It must be determined according to the principles of output size, section size, and alloy type.

03

Suppose you choose 6063 alloy profile products as the basis. In that case, the maximum circumscribed circle diameter of the product is 123mm, and the annual production capacity is 3000 tons. You can choose an 800T or 1000T aluminum press machine to meet the annual production capacity of 3000 tons.

Finally, the specific pressure and extrusion pressure should be used to check and confirm. The so-called specific pressure is the unit pressure acting on the squeeze pad.

The minimum unit extrusion force required for pure aluminum extrusion during forward extrusion is 100-150MPa, for ordinary aluminum alloys, 200-400MPa for bars, and 450-1000MPa for aluminum alloy hollow profiles and wall panels.

The extrusion force of the reverse extrusion press machine is 30% to 40% lower than that of the forward extrusion machine.

04

1. Extrusion machine molds are used differently, and the output is different.

2. The wall thickness of the raw aluminum profile also affects the output, the thicker it is, the easier it is to discharge.

3. The material of aluminum profile raw materials, bars of different materials, and the amount of output are also related to the output.

4. The rods using 6063 are easier to extrude, and the output is also high.

Summarize

Therefore, the output is related to the mold and raw materials. Generally, the extruder equipment runs 24 hours a day. The 630t is generally 5 tons, the 800t is generally 6 to 7 tons, and the 1000t is generally 8 tons.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...