Industrial ironing of clothes is a complex technique in a garment factory. Clothe ironing uses the basic principle of heat and moisture shaping of fabrics, Industrial ironing machine change the structure, surface state, and other properties with appropriate temperature, humidity, pressure, and cooling dehumidification.

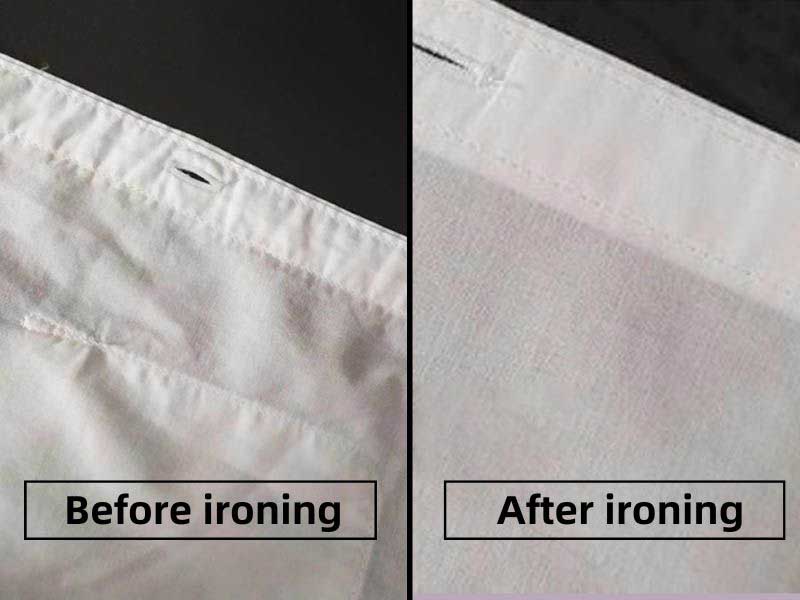

It is crucial to make clothes smooth, remove wrinkles, and improve the overall texture of clothes. There is a traditional saying in the clothing industry that “three parts sewing and seven parts ironing” shows the importance of industrial ironing technology.

Temperature is a critical factor in the industrial ironing process, serving as the primary determinant for the deformation and shaping of textiles.

Insufficient temperatures result in limited fiber deformability, thereby failing to achieve the desired heat setting.

Conversely, excessively high temperatures can surpass the tolerance threshold of the fibers, leading to detrimental effects such as melting, carbonization, or combustion of the fabric. It is essential to determine the appropriate temperature based on the specific type of fiber involved.

Furthermore, the significance of temperature extends beyond its magnitude; the duration of exposure to elevated temperatures is also vital.

Following a specified period of high-temperature treatment, it is imperative to implement rapid cooling to stabilize the textile material in its newly formed shape.

Consequently, for Industrial ironing machine the mastery of appropriate temperature settings is essential for effective garment ironing.

Humidity is also an indispensable factor in the heat-setting process. Usually, the fibers of the fabric can only be moistened, expanded, and stretched under hot and humid conditions.

Therefore, only in a moist state can we shape it into the desired shape. The water contained in the fiber is also an important factor that causes the fiber to deform.

When the humidity is appropriate, the fabric sets quickly and the ironing speed will be accelerated. When the humidity is low, the fabric is not easy to set.

Excessive humidity levels impede the drying process, resulting in materials reverting to their initial state after a certain duration. Furthermore, high humidity can negatively impact fabrics that are prone to shrinkage.

Pressure plays a crucial role in the ironing process, influencing both the quality and efficacy of the task.

Industrial ironing machine Excessive pressure may stretch fibers within the fabric, potentially causing immediate damage or contributing to premature deterioration over time.

Industrial laundry ironing machines have Too little pressure and creases are difficult to remove, meaning the garment must be ironed a second time,e and time is wasted.

For different fibers, the right amount of pressure must be applied to help eliminate wrinkles and creases, resulting in a smooth, neat ironing result.

The fabric fiber molecules are arranged neatly in new positions under the action of moisture, temperature, and pressure. When subjected to rapid cooling, it will be fixed, thereby achieving the purpose of fabric quality.

Without rapid cooling, these fiber molecules will continue to move and will not suddenly become fixed, making it impossible to characterize them.

If the fabric is cooled slowly, the moving fiber molecules will return to their original positions, leaving the fabric in a state of indeterminate zone, and the purpose of ironing and shaping cannot be achieved.

Use the suction of the industrial ironing table to absorb the air. Remove the moisture and temperature from the clothes to quickly cool them and achieve the purpose of ironing.

Efficient ironing depends on a high-standard ironer belt.

Without a high-quality ironer belt, no matter how advanced your industrial ironing equipment is, the appearance of residues and stains will still affect your ironing results. Another advantage is that it is suitable for all kinds of industrial ironing machines.

Flatwork Ironer belt material has no impurities, the higher the purity, the better the heat resistance and wear resistance.

Seamless and endless, which means that its surface is flat and smooth, without convex or concave, which can better protect the textile.

The conveyor felt belt can be used as a good transmission medium. It can evenly distribute heat to all parts of the fabric. Using an ironing belt can avoid local overheating and make the temperature of the fabric more uniform.

Thereby ensuring the flatness of the entire ironing surface and reducing wrinkles or deformation caused by uneven heating.

High-quality ironing belts can reduce damage to clothes, and ironing belts can play an insulating role.

For example, some ironing belts are designed to prevent fiber adhesion and reduce wear, which can avoid damaging clothes when changing laundry belts.

An ironing belt with a smaller diameter can distribute the pressure more evenly because the smaller ironing belt has a smaller contact area with the ironing surface, so under the same pressure, the pressure distribution is more concentrated, which helps to improve the ironing quality.

To learn more about ironing belts, you can read the following article What is ironing belt in laundry industry?

The final ironing effect is affected by many factors. Accurately master and use temperature, steam, pressure, cooling and dehumidification, ironer belt, and other factors,

Which work together to improve the ironing quality and make your clothes more beautiful and more comfortable to wear.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...