The ironing belt is an auxiliary tool used for ironing clothes.

It can be fixed between the iron and the ironing board to prevent the clothes from moving or wrinkling during the ironing process and improve the ironing effect and efficiency.

There are two main types of ironing belts, one is adjustable and can be adjusted according to the size of different irons and ironing boards.

The other is fixed and is only suitable for specific irons and ironing boards.

The ironing belt has three main functions. One is to protect the clothes and prevent the iron from damaging or discoloring the clothes.

The second is to protect the iron from contaminating or scratching the bottom of the iron.

The third is to protect the ironing board from being stained on the surface. Burns or abrasions.

The maintenance and upkeep of the ironing belt is an important measure to ensure its normal use and extend its service life.

If you ignore the maintenance and upkeep, the ironing belt may become loose, damaged, deformed, or dirty.

And other problems, affecting its function and appearance, and even Leading to quality and safety issues in ironing.

After each use, wipe the surface of the ironing belt with a clean cloth or paper towel to remove dust or stains. If there are stubborn stains

Wipe them gently with a small amount of neutral detergent, rinse with clean water, and finally Blot with a dry cloth or paper towel.

Every once in a while, apply a small amount of lubricating oil or wax to both ends of the ironing belt to make the connection with the iron and ironing board smoother and prevent friction or jamming.

Before each use, check the tightness of the ironing belt, whether it is damaged or deformed.

Whether there are foreign objects or impurities, and if there is any problem, adjust or replace it in time.

Use appropriate cleaning agents and avoid using cleaning agents containing strong acids, alkalis, or bleaches to avoid damaging the material or color of the ironing belt.

Avoid excessive stretching or bending of the ironing belt to avoid deformation or breakage, which may affect its function and lifespan.

When storing, roll up the ironing belt and place it in a dry, ventilated, and cool place away from direct sunlight or high temperatures to avoid aging or discoloration.

The effects and benefits of daily maintenance of ironing belts are as follows:

Improve equipment efficiency and life, reduce failures and losses, and save time and costs.

Keep your equipment clean and beautiful, increasing user satisfaction and trust.

Ensure the safety and hygiene of equipment and prevent adverse effects or harm to users or clothing.

According to the frequency of use and degree of wear of the ironing belts, replace the ironing belt regularly with a new one.

It is generally recommended to replace it every six months or every year.

If the ironing belt is found to be seriously damaged or deformed, it should be replaced immediately.

According to the size and shape of different irons and ironing boards, adjust the length and width of the ironing belts to maximize the contact area with the iron and ironing board, while ensuring that the ironing belts are moderately tight and not too tight or loose.

If you find that the ironing belt is slightly damaged or deformed, you can try to repair it with needle thread or glue.

But be careful not to affect the flatness and elasticity of the ironing belts. If there are still problems after repair, you should replace it in time.

Carry out maintenance according to the usage conditions of the equipment and the manufacturer’s recommendations.

Do not replace or adjust the ironing belt at will, so as not to affect the performance or safety of the equipment.

Use professional tools and personnel for maintenance.

Do not disassemble or repair the ironing belts by yourself to avoid damage or injury to the equipment.

After maintenance, check the function and status of the ironing belts to ensure that it is in normal use and error-free.

Ensure the safety and stability of the equipment and avoid ironing quality and safety problems caused by ironing belts problems.

Such as iron overheating, ironing board burns, clothing damage, etc.

Extend the service life of the equipment, and reduce equipment outage or waste caused by the replacement or repair of the ironing belts.

And improve the utilization and value of the equipment.

Reduce maintenance costs, and reduce the need to purchase new ironing belts.

Or ask professionals to repair the ironing belts due to ironing belts problems, saving users money and time.

I hope they will be helpful to you. If you have any other questions, please feel free to communicate with me at any time.

If you have any questions, you can also watch our Facebook website:www.facebook.com/nomexfelt

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

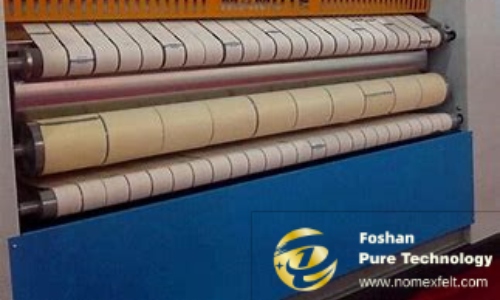

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...