Heat transfer printing is a contemporary printing process in the clothing market. It prints the pattern on the surface of the transparent film, which requires a high temperature to be transferred to the T-shirt clothing fabric.

The pattern presented is bright in color and small in chromatic aberration, which can maximize the effect required by customers.

Different heat transfer materials can meet different application groups.

And T-shirt printing has developed to the present, and different processes have created different pattern effects.

So is the heat transfer process suitable for t-shirt printing?

First, high aesthetics: The reason why manufacturers want to transfer printing with the Heat transfer paper on some textiles is to use the aesthetics of the printing after processing.

It exerts a good decorative performance on the entire textile, to enhance the aesthetics of the entire textile.

Therefore, if everyone completes this printing process, it is necessary for the final perfect printing to show the printing effect of high aesthetics.

Second, high firmness: when users use printed textiles, they will need them to maintain their beauty for a long time.

And the maintenance of its aesthetics, one of the most important aspects, requires that its printing is not prone to problems such as falling off and fading.

Therefore, the completed heat transfer paper is very important for the transfer printing process.

The user demands to present a printing effect with a very high printing firmness.

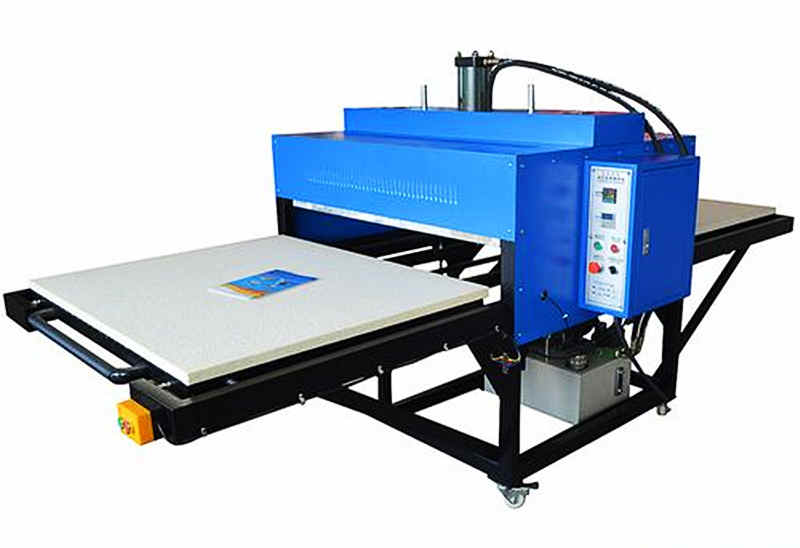

1. Hydraulic heat transfer printing

The advantages of heat transfer are good adhesion, clear pictures and texts, not easy to fade, washable,

But the breathability is relatively poor if you need to make printed T-shirts in large quantities.

Hydraulic heat transfer printing machine

2. Digital direct injection

With the continuous development of computer technology, digital printing was born.

You can shorten the production time simply by editing on the computer.

From the selection of printing and fabrics to the completion of the finished product, it only takes 1-2 hours,

Relatively speaking, it consumes fewer resources and is more environmentally friendly.

Products that meet the t-shirt printing process

Heat Transfer Felt, Heat Transfer Printer, Heat Transfer Ink, Heat Transfer Paper, Cutter, Heat Press, Nomex felt pad sublimation, Heat Tape, Heat Resistant Sheeting, Substrates.

Pure Technology has 11 years of felt production experience, the main products are: endless felt for pleating machines, heat transfer printing machines, Sanforizing machines, Compacting machines, etc. If you have related needs, please contact us: [email protected]

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...