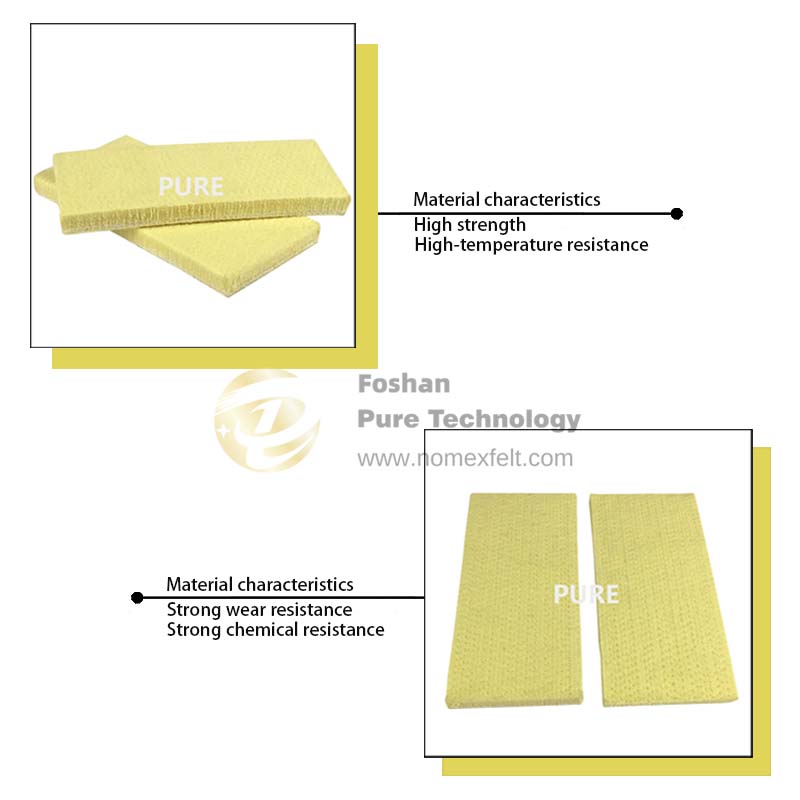

Let’s first understand the characteristics of Kevlar, which is a high-performance aramid fiber known for its superior high strength, high-temperature resistance, wear resistance, and chemical resistance. Kevlar pads are made of Kevlar fiber needle felting and woven to form a soft and strong pad.

Because of its characteristics, it is widely used in other fields such as metal products, steel plate processing, Aluminum extrusion industry, and others fields, It plays a vital role in both industrial applications and personal protection.

(1)High strength: Kevlar’s molecular structure contains repeated interchain bonds, which give its fibers extremely high tensile strength. It can provide a tensile strength of approximately 3,600 MPa. Despite its high strength, it is relatively light. This makes Kevlar pads superior to other materials in applications that require high tensile strength.

(2)High-temperature resistance: Kevlar can withstand temperatures up to 500°C and will not burn or drip when exposed to high temperatures. The amide bond is stable at high temperatures and is not easy to break so it can maintain this performance in high-temperature environments.

In the aluminum industry, the heat-resistant felt pad can be used as a heat insulation material to protect aluminum from direct contact with the cooling bed surface.

(3)Abrasion resistance: When subjected to friction or pressure, Kevlar Felt Skid Plates can withstand large loads without significant wear or damage because the strength and rigidity of these interchain bonds can absorb and disperse impact forces, thereby improving their wear resistance.

(4)Chemical resistance: Kevlar is highly resistant to many chemicals, including acids, bases, and organic solvents. Thanks to the amide bonds in its molecular structure, these bonds are stable in chemical environments and not easily destroyed. This chemical resistance allows Kevlar pads to maintain their performance in chemically corrosive environments, protecting equipment and personnel from chemical corrosion.

Material properties

Felt pads are made of Kevlar fibers, which have extremely high tensile strength and high temperature and wear resistance; cotton pads are made of natural cotton fibers, which have good air permeability and comfort, but are not as good as Kevlar in strength and wear resistance; ordinary synthetic fiber pads, although they provide certain strength and wear resistance, are not as good as Kevlar pads in cutting performance.

High temperature and wear resistance

In high-temperature environments, kevlar pads perform much better than cotton and ordinary synthetic fiber pads. The heat-resistant temperature range of common cotton does not exceed 400°C. Kevlar fiber has excellent wear resistance, which allows it to maintain its performance under repeated friction.

Cotton pads are not as good as Kevlar pads. Because cotton fiber has relatively low strength and is more easily damaged when subjected to repeated friction, ordinary synthetic fiber pads are generally better than cotton in wear resistance, but still not as good as Kevlar pads, so they may not perform as well as Kevlar in high-demand applications, especially in specific occasions where aluminum industrial felt is required.

Chemical resistance and cutting performance

Kevlar Felt has good resistance to most chemicals and can maintain their performance in harsh chemical environments; cotton fibers have weaker chemical resistance and may be corroded or damaged in certain chemical environments; ordinary synthetic fibers have good chemical resistance, but this chemical resistance varies depending on the specific fiber type and manufacturing process.

Kevlar fiber is known for its high tensile strength, which makes it very good at cutting performance; cotton fiber has relatively poor cutting performance because it has low tensile strength and is more likely to break when subjected to cutting forces; ordinary synthetic fiber pads are generally better than cotton in terms of wear resistance, but still not as good as Kevlar.

The cost of Kevlar pads is higher than that of traditional materials because the production cost of Kevlar fiber is high. Still, the performance of this material can bring higher returns.

The strong wear resistance and high-temperature resistance of Kevlar pads mean that they can maintain a longer service life in a specific working environment, and the replacement frequency will be reduced during use, thereby reducing the cost of long-term replacement; its durability and stability can reduce the downtime of the machine, unlike other materials that are easily damaged, reducing the losses caused by downtime. Although the investment cost of Kevlar pads is relatively high, the comprehensive long-term economic benefits are significant.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...