In modern industrial production, laundry belts are core components of laundry equipment, production line conveyor belts, and other scenarios. Their stability directly affects production efficiency and costs.

However, there are long-term problems, such as wear and looseness, and traditional maintenance methods (such as glue bonding) are inefficient and ineffective.

Taking the laundry industry as an example, high temperature and high humidity environments and detergent corrosion can easily lead to belt failures, and monthly downtime losses can reach tens of thousands of dollars.

Traditional maintenance’s limitations include time-consuming manual operation, low bonding strength (the interface debonding rate exceeds 30%), and a lack of standardized tools.

Technical solution: Through material innovation and intelligent design, the ironer belt and belt clamps can improve maintenance efficiency by more than 60% and reduce the failure rate to less than 5%.

This article will deeply analyze these two tools’ functional characteristics, application scenarios, and selection strategies to provide you with the best solution.

Ironer belts are key components in industrial ironing equipment. Our ironer belt is made of Nomex and polyester. Installed on the roller or conveyor system of the ironing machine, it is used to convey clothes and other materials smoothly during the ironing process.

Through stable transmission, it ensures that the surface of the clothes is in full contact with the ironing parts (such as rollers or pressing plates), avoiding local overheating or uneven ironing and ensuring the quality of ironing.

It reduces the direct damage of high temperature to sensitive materials (such as chemical fiber fabrics) and prevents clothes from sticking to the equipment; it supports automated continuous operation.

This is suitable for large-scale laundry factories, garment factories, and other scenarios, significantly increasing the processing volume and reducing the need for manual operation.

Mainly used in industrial ironing machines, washing machines, folding machines, and other equipment commonly seen in hotels, hospitals, textile factories, and professional laundry service agencies.

It is an indispensable component in the modern automated ironing process. Regular maintenance (such as cleaning and adjusting tension) can extend its service life and ensure stable ironing results.

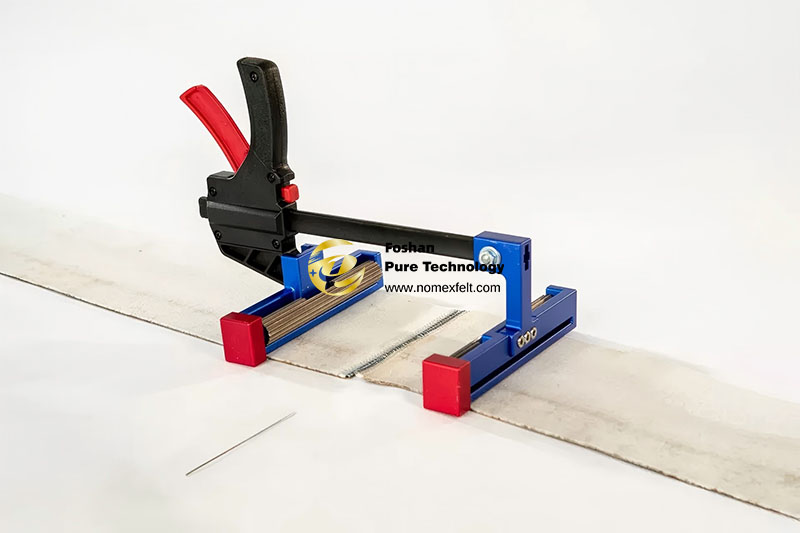

Belt clamps are special tools that use hydraulic or mechanical structures to fix and adjust the belt tension. They are divided into two types:

Stretching clamps: suitable for tension calibration during belt installation.

Connecting clamps: used for quick splicing of multiple belt sections, supporting tool-free disassembly.

Belt clamps provide extra security and stability, ensuring the belt stays in place and does not slip or loosen.

Belt clamps are a must for any conveyor belt system, ensuring a strong and tight connection between belts for smooth and efficient movement of materials.

Self-maintenance: Operators can complete tension adjustment without professional training, reducing technical dependence on manufacturers.

|

Belt Clamps |

CBS-F4 Belt Clamps |

CBS-F7 Belt Clamps |

CBS-Q18-48 Belt Clamps |

|

Belt type |

Cotton, Rubber-covered, and PVC heavy-duty |

Cotton, Rubber-covered, and PVC heavy-duty |

Cotton, Rubber-covered, and PVC heavy-duty |

|

Load capacity |

400 lb |

400 lb |

1200 lb |

|

Belt thickness |

up to 8 mm |

up to 8 mm |

1 mm to 8 mm |

|

Belt width |

up to 4″ |

up to 7″ |

up to 18″,48″ |

|

Material |

Heat-treated extruded aluminum; stainless knurled steel roll; plastic clamp. |

Heat-treated extruded aluminum; stainless knurled steel roll; plastic clamp. |

Heat-treated extruded aluminum; heat treated steel blades; plastic clamp |

Installation steps for flatwork ironer belt: First, make sure to turn off the power, take out the laundry belt, find the interface, and insert the half-pull-out connecting strip from the conveyor belt interface.

Then, turn on the power and adjust the machine speed to a slow rotation through the speed regulator. The new conveyor belt will pass through the rollers one by one under the drive of the original conveyor belt.

After a full rotation, pause the machine and return the connecting strip of the original laundry belt to its original position. Insert the connecting strip into the newly threaded conveyor belt and leave half of it.

Continue to repeat the previous steps until all conveyor belts are installed. After all new conveyor belts are installed, replace the original reserved conveyor belt.

Adjust the gap and tension between the conveyor belts until they are in a satisfactory working state.

Common adjustment methods for ironing belts include the tension adjustment method, parallel adjustment method, centering adjustment method, etc.

Tension adjustment method: Tension adjustment is achieved by adjusting the tension device of the ironing machine.

Different machines may have different tension adjustment methods. Therefore, before operating the machine, it is recommended to read and understand the relevant manual to ensure that the tension device is adjusted correctly.

The selection of industrial belt clamps and laundry belts must take into account both performance adaptation and cost-effectiveness. The following provides decision-making from the perspective of channel selection and technical indicators.

|

Evaluation Dimensions |

E-commerce platform |

|

|

Customization |

Most standard sizes |

Custom sizes |

|

Delivery cycle |

3-7 days (international logistics) |

7-15 days (need to confirm details) |

|

Technical Support |

None (depends on the instruction manual) |

Installation guidance + maintenance training |

Decision-making suggestions:

Emergency purchases: Give priority to mainstream e-commerce platforms and screen sellers to ensure quality.

Long-term needs: sign contracts with leading manufacturer of industrial felts and enjoy long-term discounts by choosing us.

Our ironing belts are suitable for washing machines, sheet ironing machines, folding machines, etc.

Suitable for various machines such as Primus ironing machines, commercial ironing machines, Electrolux ironing machines, Stefabric ironing machines, gas heated ironing machines, Chicago ironing machines, and Jensen industrial ironing machines.

Performance definition: The material must maintain structural stability under continuous high temperatures (200°C~280°C) without deformation, softening, or burning.

Nomex belt: temperature resistance below 260°C, suitable for industrial-grade high-temperature ironing equipment, excellent resistance to heat aging. Polyester belt: temperature resistance 180°C, lightweight, and cost-effective.

Our ironing belts resist fuzzing, pilling, or breakage caused by mechanical friction, extending the service life of the belts to more than 1,000 hours. The multi-layer composite process increases the service life by 3 times.

To resist erosion by steam, acidic/alkaline detergents (pH 3~11), grease, etc., and to prevent material expansion or embrittlement, our products will undergo chemical immersion tests to ensure that they meet standard requirements and have no performance degradation.

Case 1: An Indian laundry shop optimizes maintenance costs through an independent replacement solution.

Indian Laundry found that frequent damage to equipment belts led to rising maintenance costs.

The traditional model of relying on external manufacturers for replacement has problems such as long cycles and high costs (for example, the machine requires 5 different sizes/materials of belts, involving rubber, flexible materials, etc).

✓ Single maintenance time reduced by 60%

✓ Annual maintenance cost reduced by 45%

✓ Equipment availability increased to 98%

Self-replacing belts have freed us from passive waiting. Now, new employees only need 1 hour of training to complete belt replacement independently.——Indian laundry equipment supervisor.

The application of laundry belt and belt clamp technology marks the transformation of industrial maintenance from “passive repair” to “active prevention”.

Through the practical data of Indian Laundry (maintenance cost decreased by 45%) and the repair case of a manufacturing company (single cost saving of 76%), we verified the following core values:

Cost optimization: Modular design reduces spare parts inventory pressure, and the life cycle cost optimization rate reaches 30%-50%.

Efficiency revolution: Standardized tools reduce maintenance hours to 1/3 of the traditional mode, and equipment availability has increased to more than 98%.

Risk controllable: The self-locking system controls the human error rate to less than 0.5%, eliminating potential safety accidents.

Many laundries around the world have used our belts, and the belt life has doubled, and the maintenance cost has dropped by 45%, helping companies save more.

By choosing us, you can enjoy exclusive services. You only need to provide size parameters, and we can help you with exclusive customization.

We will escort you from pre-sales to after-sales. Choosing us is not only choosing accessories but also choosing the guarantee of continuous profitability.

If you want to know more, please feel free to contact us

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...