Hot press printing is a printing method that uses high temperatures to transfer patterns from printing paper to substrates.

It is widely used in the production of printed matter of various materials and shapes.

Such as clothing, shoes and hats, bags, household items, etc.

The quality and efficiency of heat press printing largely depend on the protective layer or transfer layer used on the printing press.

They can prevent damage or deformation of the machinery caused by high temperatures and ensure sufficient contact time and distance between the pattern and the substrate.

In this regard, the endless felt blanket is a very excellent seamless inelastic fiber material.

It is made by high-temperature hot pressing or hot pressing printing and other processes.

It has the characteristics of flatness, smoothness, wear resistance, high-temperature resistance, etc.

And can be used in hot It plays an important role and advantage in printing.

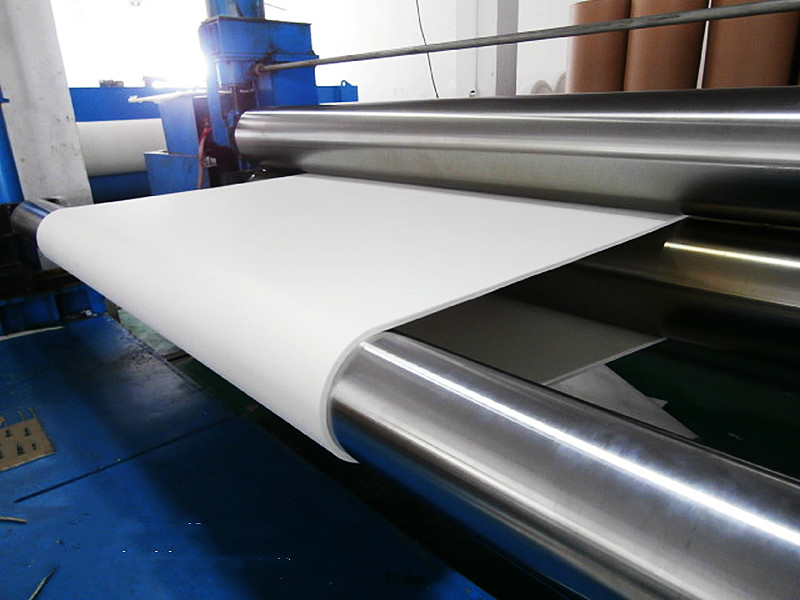

The endless felt blanket is a continuous fiber layer that does not require sewing or joining.

It does not have any seams or cracks, elasticity, or stretchability.

So it can maintain its stable and uniform thickness and width, adapting to various needs.

Equipment and workpieces of various shapes and sizes.

The surface of the endless felt blanket has been processed by high-temperature hot pressing or hot pressing printing to make the surface very flat and smooth without any burrs or bumps. So it can effectively prevent wrinkles and bubbles and improve the quality and effect of printing or processing.

The fiber material of the endless felt blanket has been specially selected and mixed to make it highly wear-resistant and high-temperature resistant.

It can withstand high temperatures up to 230°C without being scorched or deformed, and can also resist long-term friction.

And wear, extending its service life.

Endless felt blanket is widely used in heat press printing, textile, washing, and steel.

And other industries a protective layer or transmission layer is required for various equipment and processes.

In these industries, endless felt blankets can improve the quality and efficiency of printing or processing.

Protect equipment and workpieces from damage, and extend their service life.

In the heat press printing industry, the endless felt blanket is mainly used as a printing method to transfer patterns from printing paper to the substrate.

It can be used as a protective layer or transmission layer for heat press printing machines to prevent high temperatures from causing damage to machinery.

Or deformation, and can ensure sufficient contact time and distance between the pattern and the substrate.

Improving the quality and efficiency of hot press printing.

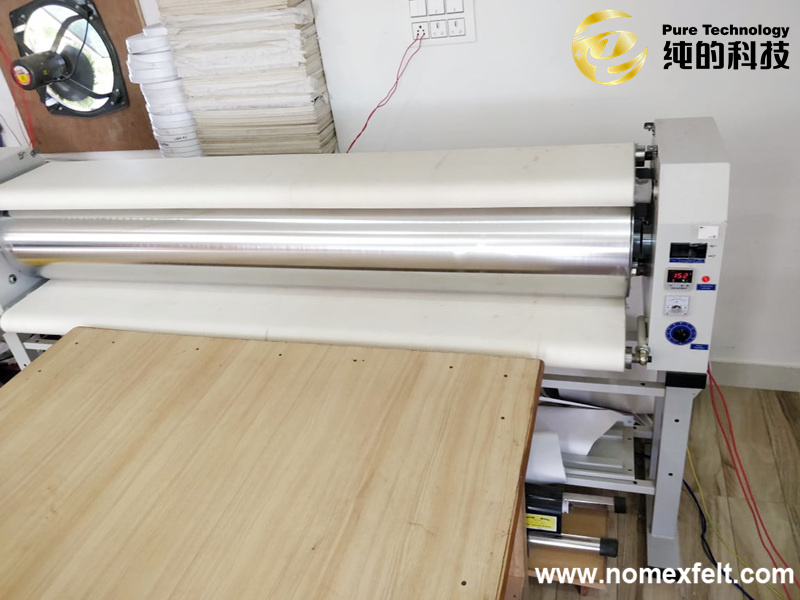

A protective layer of heat press printing machine:

The endless felt blanket can be covered on the upper or lower roller of the heat press printing machine to form a protective layer that can prevent damage or deformation of the machine caused by high temperature and maintain the stability and accuracy of the machine.

The protective layer of the endless felt blanket can be selected in different thicknesses and widths according to the requirements of different printing machines and printed products to adapt to different temperatures, pressures, and speeds.

Transmission layer of heat press printing machine:

The endless felt blanket can be sandwiched between the printing paper and the substrate to form a transmission layer.

Which can ensure sufficient contact time and distance between the pattern and the substrate to improve the transfer efficiency of the pattern. and quality.

The transmission layer of the endless felt blanket can choose different fiber materials and mixing ratios according to the characteristics of different printing papers and substrates to adapt to different ink types and substrate materials.

In the textile industry, the endless felt blanket is mainly used for hot pressing, ironing, shaping, finishing, and other processes of textiles.

It can be used as a protective layer or transmission layer for heat presses, ironing machines, and shaping machines.

Other equipment prevents Textiles from becoming contaminated or damaged at high temperatures and can improve the performance and quality of textiles.

A protective layer of heat press:

The endless felt blanket can be covered on the upper or lower roller of the heat press to form a protective layer that can prevent damage or deformation of the machine caused by high temperatures and maintain the stability and accuracy of the machine.

The protective layer of the endless felt blanket can be selected in different thicknesses and widths according to the requirements of different heat presses and textiles to adapt to different temperatures, pressures, and speeds.

Transmission layer of heat press:

The endless felt blanket can be sandwiched between the textile and the heat press to form a transmission layer.

Which can ensure that the textile is subject to uniform pressure and temperature at high temperatures.

Improving the heat pressing effect and quality of the textile.

The transmission layer of the endless felt blanket can choose different fiber materials and mixing ratios according to the characteristics of different textiles to adapt to different textiles.

Explain the principle of hot press printing:

A printing method that uses high temperature to transfer patterns from printing paper to substrate.

The principle of hot press printing is to use the characteristics of the ink on the printing paper to melt or sublimate at high temperatures to transfer the pattern from the printing paper to the substrate to form a strong printing layer.

There are two main types of inks for heat press printing:

melting and sublimation. Melted ink is an ink composed of thermoplastic resin, pigments, additives, etc.

It melts at high temperatures and then solidifies at low temperatures to transfer the pattern to the substrate. Sublimation ink is an ink composed of sublimation dyes, dispersants, adhesives, etc.

It sublimates into a gaseous state at high temperatures and then condenses on the substrate at low temperatures.

Thereby transferring the pattern to the substrate.

Introducing the process of hot press printing: divided into printing paper production.

Hot press printing machine settings, hot press printing operation, and other steps.

Printing paper production:

The pattern is produced electronically or optically and then printed on special printing paper through an inkjet printer or laser printer.

The selection of printing paper depends on the type of ink used in hot press printing and the characteristics of the substrate.

Generally, printing paper is required to have good smoothness, heat resistance, moisture resistance, wear resistance, etc.

The production of printing paper must ensure the clarity of the pattern.

The degree of color restoration, the uniformity of the ink, etc.

Generally, high-resolution, high-color gamut and high-precision printing equipment must be used.

Place the printing paper and substrate between the upper and lower rollers of the heat press printing machine respectively

Adjust the temperature, pressure, speed, and other parameters of the heat press printing machine.

The selection of a hot press printer depends on the type of printing paper and the shape of the substrate.

The size of the pattern the number of prints, etc.

Generally, the hot press printer is required to have good temperature control, pressure control, speed control, etc.

The settings of the hot press printing machine should be determined according to the characteristics of the printing paper.

The characteristics of the substrate, the characteristics of the pattern, etc.

Generally, the temperature is required to be high enough, the pressure is large enough

The speed is appropriately fast to ensure complete transfer and firm adhesion of the pattern.

Hot press printing operation: start the hot press printing machine to put the printing paper and substrate under pressure at a high temperature, so that the pattern is transferred from the printing paper to the substrate

And then separate the printing paper and substrate to obtain hot-pressed printed matter.

During hot press printing operations, attention should be paid to the alignment, and tension.

And flatness of the printing paper and substrate to prevent defects such as misalignment, wrinkles, and bubbles.

During hot press printing operations, attention should be paid to the timing and method.

And conditions of printing paper and substrate separation to prevent defects such as adhesion, residue, and damage.

Explain the role of the endless felt blanket in hot press printing:

as a protective layer or transmission layer on the hot press printing machine, it can prevent damage or deformation of the machine caused by high temperature and can ensure sufficient contact time and distance between the pattern and the substrate.

The function of the protective layer:

The endless felt blanket can cover the upper or lower roller of the heat press printing machine to form a protective layer that can prevent damage or deformation of the machine caused by high temperature and maintain the stability and accuracy of the machine.

The function of the transmission layer:

The endless felt blanket can be sandwiched between the printing paper and the substrate to form a transmission layer.

Which can ensure sufficient contact time and distance between the pattern and the substrate.

And improve the transfer efficiency and quality of the pattern.

High-temperature resistance:

It can withstand high temperatures up to 230℃ without burning or deforming, maintaining its flat and smooth surface.

Reasons for high-temperature resistance:

The endless felt blanket is made by high-temperature hot pressing or hot pressing printing.

Its fiber materials are specially selected and mixed to make it have high heat resistance and thermal stability.

Benefits of high-temperature resistance:

The endless felt blanket can continue to work at high temperatures without affecting the speed and effect of printing due to burning or deformation, improving the production efficiency and quality of printing.

Wear resistance:

It has good wear resistance and will not be damaged or fall off due to long-term friction, extending its service life.

Reasons for wear resistance:

The endless felt blanket is made of seamless and inelastic fiber layers.

It does not have any seams or cracks, elasticity, or stretchability, so it can resist long-term friction and wear.

I hope they will be helpful to you. If you have any other questions, please feel free to communicate with me at any time.

If you have any questions, you can also watch our Facebook website:www.facebook.com/nomexfelt

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...