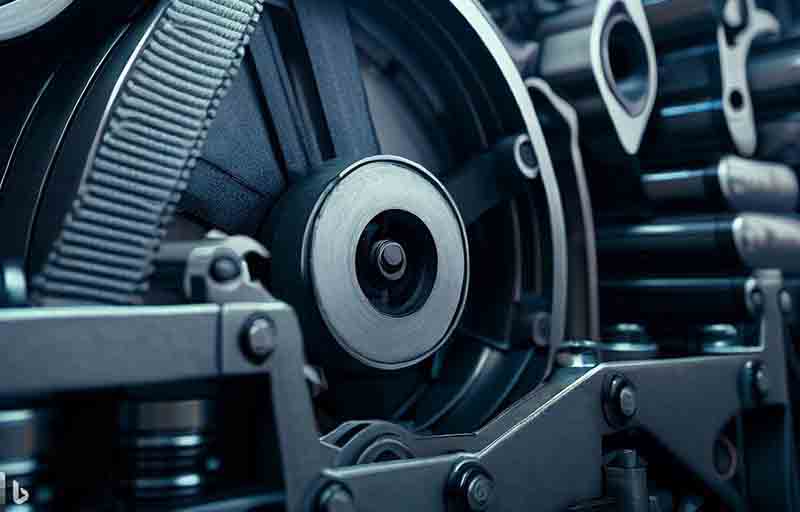

The high-temperature timing belt is a kind of rubber product used for synchronous transmission.

Which is widely used in the aluminum extrusion processing industry.

High-temperature timing belt has the advantage of high-temperature resistance.

Wear resistance, oil resistance, aging resistance, etc.

But they will also encounter various damage problems in the use process, such as fracture, cracking, stripping, slip, etc.

These problems will not only affect the normal work of the timing belt but also cause damage to the equipment or accidents.

Therefore, timely discovery and treatment of high-temperature timing belt damage, as well as taking effective preventive measures.

Is an important content to ensure the safe operation of equipment and extend the life of the timing belt.

repair and replacement: Repair refers to using special tools and materials to repair or glue the damaged parts of the timing belt to restore its function and performance.

Replacement refers to replacing the broken timing tape directly with a new timing tape to avoid further damage or failure.

The choice of repair and replacement should be comprehensively considered according to the degree of damage, location, cause, influence, and other factors of the time series.

In general, if the damage to the timing belt is slight, such as slight scratches, cracks, or peeling on the surface.

And does not affect its regular work, it can be treated with repair methods;

If the damage to the timing belt is serious, such as fracture, cracking, or peeling of a large area, or affecting its synchronous transmission function, or there is a safety hazard, it should be replaced.

Bonding method: Use special glue or film to bond the damaged part of the timing belt to restore its integrity and strength. The bonding method is suitable for cracking or peeling a small area on the surface of the sequential strip.

Sewing method: Suture the damaged part of the timing belt with a needle and thread to restore continuity and stability.

The seam method is suitable for fracture or cracking with a small range of time series.

Patch method: Cover the damaged part of the timing belt with a patch made of the same or similar material.

And bond with glue or film to restore its integrity and strength. The patch method is suitable for cracking or stripping with a large area in time series.

Disassembly: Stop the operation of the device, and disconnect the power supply.

And then use a unique tool to remove the timing belt from the synchronous wheel.

Taking care not to damage the synchronous rotation or other parts.

Clean: Wipe the contact parts of the synchronization wheel and timing belt with a clean cloth or paper towel, remove dust, oil, debris, etc., and keep it clean and dry.

Installation: Use special tools to install the new timing belt on the synchronous wheel.

Pay attention to adjusting the tension and position of the timing belt so that it is closely matched with the synchronous rotation, with no sliding or beating phenomenon.

Check: Start the equipment, observe the operation of the timing belt, and check whether there is abnormal sound, vibration, wear, etc.

Confirm that there is no problem, and then officially put it into use.

Good material selection and design: According to the working conditions and requirements of the equipment.

Select the appropriate materials and specifications for the high-temperature timing belt to ensure that it has sufficient strength.

Wear resistance, high-temperature resistance, and other properties.

At the same time, according to the characteristics and parameters of the timing belt

The material, shape, size, and quantity of the synchronous wheel are reasonably designed to ensure a good match and coordination with the timing belt.

Install and adjust the timing belt correctly according to the instruction manual of the equipment and timing belt to avoid being too tight or too loose

Resulting in too large or too small tension, affecting its life and efficiency.

Regularly check the operation of the timing belt.

Timely detect and deal with abnormal phenomena, such as loosening, sliding, jumping, wear, etc.

Clean and lubricate the timing belt and synchronous wheel regularly, and remove dust, oil, debris, etc.

To prevent it from causing damage to the timing belt or affecting its transmission effect.

Or take cooling measures, such as ventilation, heat dissipation, etc., to prevent its deformation or aging due to overheating.

Timely replacement: According to the timing belt’s service life and wear degree.

Convenient replacement of the new timing belt to avoid equipment failure or accidents caused by the use of expired or damaged timing belts.

At the same time, when replacing, attention should be paid to maintaining the consistency and compatibility of the synchronization wheel and timing belt.

Do not replace the timing belt of different brands or specifications at will.

In short, the high-temperature timing belt is an important synchronous transmission component.

The use of the process should pay attention to the timely discovery and treatment of its damage problems.

As well as effective preventive measures to ensure the safe operation of the equipment and extend the life of the timing belt.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...