Heat press printing technology, also known as heat transfer printing technology, is a process of transferring images or patterns from one medium to another, viral in textile printing. Its principles include image carrier; sublimation dye; heat embossing process; sublimation and penetration; cooling and fixation; and post-processing.

Temperature control: Temperature is a key factor affecting dye sublimation. For Heat Press Printing Felt Blanket, the appropriate temperature range is usually 180-230°C, ensuring that the dye can fully sublimate and evenly penetrate the felt fiber.

Pressure control: Appropriate pressure helps to ensure close contact between the transfer paper and the felt blanket, thereby obtaining a uniform printing effect. Insufficient or excessive pressure may result in uneven color or blurred patterns.

Time control: Optimization of heat pressing time is essential to ensure the fixation of dyes on the felt blanket. Too short a time may result in incomplete transfer, while too long a time may result in faded colors or blurred patterns.

Equipment accuracy: The processing accuracy of the heat press determines the uniformity of temperature and pressure during the heat pressing process, which directly affects the quality and efficiency of printing.

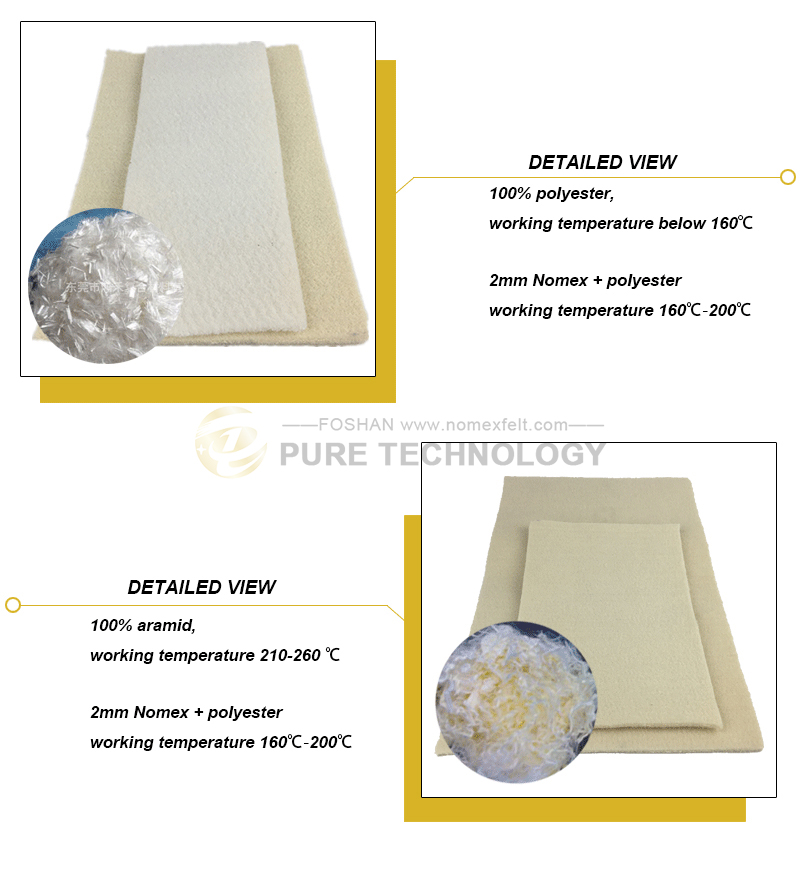

Material selection: High-quality dyes and transfer papers are essential for the production of high-quality Heat Press Printing Felt blankets. The quality of the fiber material will also affect the printing effect.

Environmental conditions: Temperature and humidity control in the production environment is very important to maintain the stability and repeatability of the heat press printing process.

Operating skills: The operator’s experience and skills are crucial to reducing color differences and improving printing quality. Regular training and experience accumulation help improve the operation level.

Post-processing process: Post-processing steps such as cooling and shaping after printing are critical to ensure the durability and color fastness of the pattern.

Color fastness: The color fastness of heat transfer printed fabrics depends on the processed fabric, transfer paper, and dye, as well as the printing process conditions. For synthetic fibers such as polyester, color fastness is generally good.

Standardized production conditions:

Ensure that the temperature, pressure, and time are consistent during each production process.

Calibrate equipment:

Regularly calibrate the heat press and other related equipment to ensure their stable performance and precise temperature and pressure control.

Use high-quality materials:

Select high-quality dyes and transfer papers to ensure their uniformity and consistency.

Optimize heat press process parameters:

Determine optimal heat transfer parameters—temperature, pressure, time—via experiments and strictly follow them.

Pre-treat textiles:

Appropriately pre-treat textiles before printing, such as washing, bleaching, or softening, to ensure that the dye can be evenly absorbed.

Control environmental conditions:

Maintain a stable production environment, including temperature and humidity control, to reduce the impact of environmental factors on the printing process.

Use automation technology:

Use automation equipment to reduce human operating errors and improve the consistency of the production process.

Conduct small batch tests:

Before large-scale production, conduct small batch tests to detect and adjust possible color difference problems.

Quality inspection and monitoring:

Implement a strict quality inspection process and conduct color difference inspection on each batch of products to ensure the consistency of product color.

Use professional software:

Use color management systems and software to predict and adjust color differences to ensure color accuracy.

Establish color standards:

Establish a set of color standards and reference systems for comparing and evaluating colors during production.

Post-processing optimization:

Optimize the cooling and setting process after printing to ensure color stability.

Heat-pressed felt blanket production merges traditional felt-making with modern heat transfer tech.

The following are the key steps and special equipment required to produce this felt blanket:

These steps and tools ensure personalized, high-quality, and durable heat press printed felt blankets. The felt blanket, with its unique production and material selection, is widely used across industries like printing, textiles, leather, chemicals, advertising, and more.

In the heat press printing process of hot press printed felt blankets, temperature control has a vital impact on the quality of felt.

The following are several key points about the effect of temperature control on the quality of felt:

In summary, temperature control plays a decisive role in the production process of hot-pressing printed felt blankets. It not only affects the physical properties and pattern quality of the felt but also affects production efficiency and cost. Therefore, precise control of temperature in the hot pressing process is the key to ensuring the quality of the felt blanket.

Pressure control:

The printing pressure must be evenly distributed to ensure that the pattern is evenly transferred on the felt blanket. Insufficient pressure leads to uneven prints; excessive pressure risks fiber damage or pattern distortion.

Time control:

The duration of hot pressing is equally important to the printing effect. Insufficient time may result in weak printing, while too long a time may cause excessive dye penetration or blurred patterns.

The quality of transfer materials:

The quality of transfer paper and ink directly affects the printing effect. High-quality transfer materials can provide clearer and more durable printing effects.

Pretreatment of felt blankets:

Pre-treat felt blankets for dye receptivity: clean, pre-shrink, or stretch.

Equipment accuracy and maintenance:

The accuracy and maintenance of the heat press will also affect the printer heat press effect. The equipment needs to be calibrated and maintained regularly to ensure the consistency and accuracy of temperature, pressure, and time.

Post-processing process:

Post-print processes like cooling and washing ensure pattern color and texture durability.

Felt blanket material and structure:

Different felt materials and structures have different absorption and retention capabilities for dyes, which will also affect the printing effect.

Pattern design:

The complexity of the pattern, the number of colors, and the design details will affect the difficulty and final effect of hot press printing.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...