product

Highest temperature:600°C short-term (15 minutes), Long-term 550°C. Only suitable for the runout table and cooling table (high temp zone).

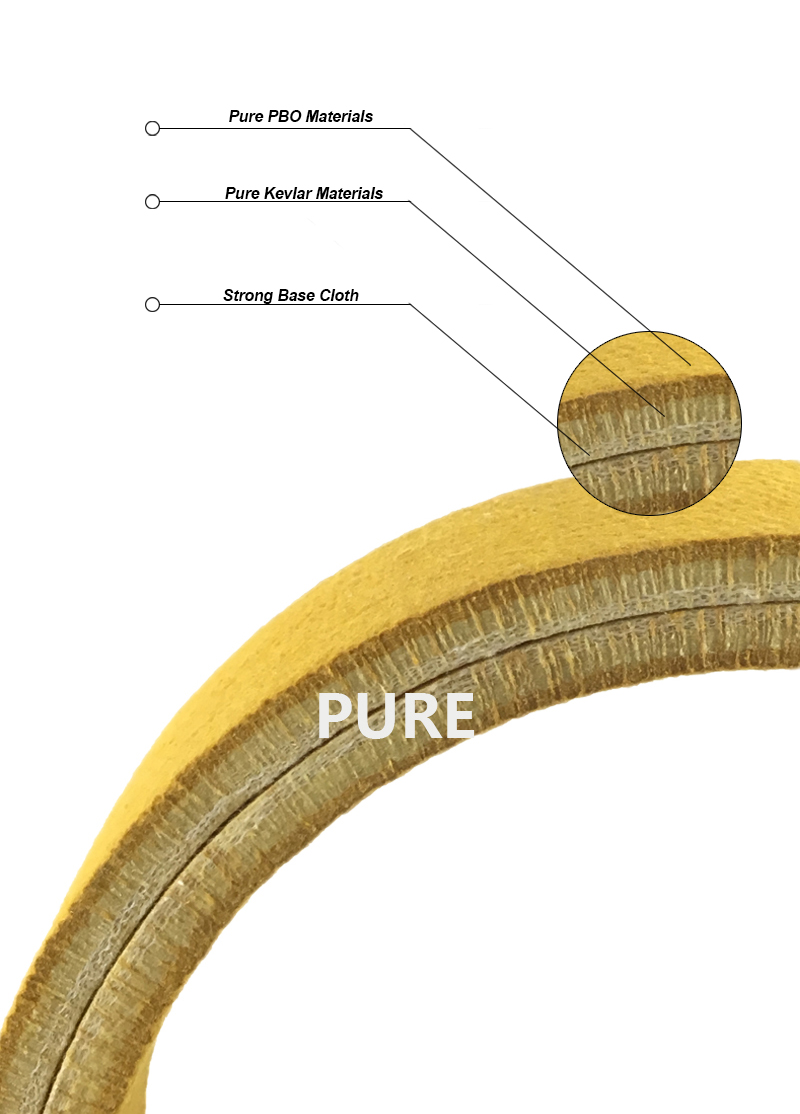

PBO Endless Felt Belt

Applied to the primary aluminum handling system of extrusion line for producing large and irregular aluminum profiles

High density, temperature resistance, and wear resistance, smooth cut, no delamination, no hair, no pollution to aluminum profile

| Brand Name: | PURE | Type: | 3+7PBO/Kevlar,4+6PBO/Kevlar,2+8PBO/Kevlar |

| Model Number: | Belts-PK | Material: | 3mm PBO + 7mm Kevlar |

| Color: | Brown+Yellow | Temperature: | 600 ℃ |

| Density: | 450g/m²/mm | Technique: | Needle Punch |

| Load Capacity: | Below 2000T UST Extruder Aluminum Profiles | Dimension(L*W*H): | Customized Size |

| Application: | Mainly use 5pcs after interrupting saw | Place of Origin: | Guangdong, China |

● Endless and seamless attribute conveyor felt belt without joints and seams. It has no weaknesses and has a flat thickness.

● The endless belt conveyor is flat with no blemishes, bumps, scales. The surface is extremely smooth. Will not contaminate aluminum. especially suitable for the production of aluminum products with extremely high requirements for electrophoretic surfaces and polished surfaces.

● The felt material is 100% pure, without any impurities, the higher the purity, the higher the quality, the heat-resistant temperature meets the requirements, the abrasion resistance, and the effective use time is longer than other manufacturers.

The industrial high temperature felt belt manufactured by Foshan Pure Technology can use T/T, Paypal, Western, Union, L/C, and other payment methods.

? Click the button in the bottom right corner to contact us for more payment methods. ?

PBO Felt Belt Detailed View

Click here to Get the Price Now!

● PBO Seamless Felt belt is used in the first and second handling table, generally only used in large-tonnage extruders. Felt Belt for aluminum extrusion.

We actively promote the modern enterprise management system and were awarded ISO9001:2008 EWC quality system certificate etc.

We have QC staff to inspect every process and raw materials to ensure the products in good quality. Advanced equipment like mechanical needling and carding machine etc.

|

PBO material is prepared by solution polycondensation of 4,6-diaminophenol hydrochloride and terephthalic acid with polyphosphoric acid as solvent. It is a reinforcing material for composite materials developed by the United States in the 1980s for the development of the aerospace industry. |

|

|

Carding Carding machine opens and combs heat resistant fibers to remove impurities. |

|

|

Weaving Laying The fiber enters the web-laying machine, takes an approach to automation using robots, ensures consistent high quality and productivity. |

|

|

Hardened Full resin or semi-resin treatments are available to improve the wear resistance and durability of the PBO Kevlar conveyor belt. It also prevents aluminum swarf or dirt from sticking to the industrial felt, reducing damage to the surface of aluminum profiles. |

|

|

Cutting The PBO heat resistant belt is cut with an electric rotating fabric cutting machine. Whether in terms of specifications or quality, Pure® felt tubes can perfectly meet customer needs. Using superb technology and machinery, cut out the size required by the customer, and cut out the edge-free Industrial felt roller. |

|

|

Inspection All the finished products will be inspected by our professional-quality control staff with metal detector equipment, to ensure all products are inspected and there are no broken needles inside the heat proof PBO belt covers. Foshan Pure technology always insists that we’ll only deliver the goods to our customers after our products pass a series of rigorous tests. |

|

|

The heat resistant felt belt packaging in the aluminum extrusion industry uses a transparent shrink film to wrap the entire felt to reduce the volume of each product, facilitate packing in the box, and be waterproof. |

|

600℃ PBO products. #aluminumextrusion#PBOroller #coolingtable pic.twitter.com/o9e2YrPDaw

— Foshan Pure technology co., LTD (@nomexfelt_com) October 28, 2022

● Professional technical team to provide you with tailor-made services.

According to the industrial extrusion belting specifications and requirements provided by customers, design and manufacture products that meet the requirements.

● Professional instruction to achieve the purpose of reducing costs, such as which level of cooling bed to use which temperature Felt Conveyor Belt. How to use the one that can extend the life of the felt belts.

● Professional aluminum extrusion plant construction experience, one-stop service, in addition to high temp felt, it also provides extrusion press, aging furnace, mold, casting platform, Aluminum profiles packing machine, correction machine, aluminum motor, handing system, etc.

Q: What information do I need to provide?

A: Need to provide Seamless belt size, machine model and picture, delivery address, and zip code to calculate shipping

Q: What is the process of placing an order?

A: Contact us for PBO conveyor belts size and quotation, We provide you with an invoice-remit the money to the bank account-arrange the heat resistant felt production after receiving the payment-settle the balance before shipment- send out the felt rollers – receive the goods

Q: Are there any additional costs?

A: Additional taxes and fees are determined by your local customs duties

Q: Where is the origin of the fiber?

A: The low-temperature fiber polyester has a temperature resistance of 180 degrees and is produced in Yantai, China.

Nomex, a medium-temperature fiber with a temperature resistance of 280 degrees, comes from the USA.

The high-temperature fiber Kevlar has a temperature resistance of 480 degrees and is produced in the USA.

The PBO fiber has a temperature resistance of 600 degrees and the place of origin comes from Japan.

Q: Will the color of the PBO endless belt conveyor stay the same? What factors determine if the color changes?

A: The PBO conveyor belts will change color regardless of whether it is used or not.

When the PBO felt belt is not in use, it will be affected by light and air oxygen, and it will turn into a darker yellowish brown, but it will not shine.

In the state of use, it will become dark brown under the influence of temperature, and the surface will be shiny.

We are to provide high quality supplies and solutions to reduce marginal costs for the boss who has problems in purchasing machinery spare parts. Leading manufacturer of heat resistant felt belts Nomex felt factory – Pure Technologies Ltd.

Welcome to our company website, thank you for your letter, we will give you a reply in the first time, would you please leave your information and contact way!